The purpose of an electric motor is to provide power to produce a certain speed and torque. However, some applications require high torque at low speed, and in these cases, it is more economical to use a geared motor instead of a pure electric motor large enough to deliver the required torque.

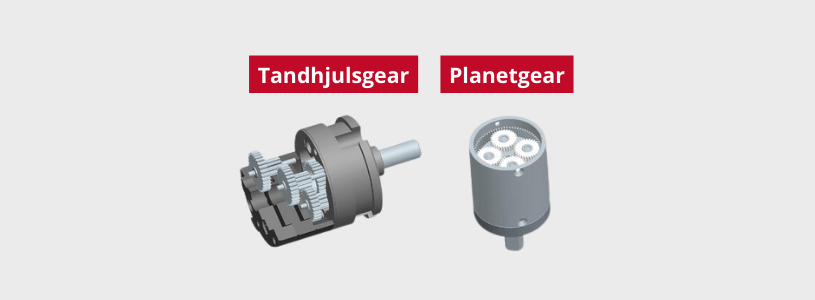

A gear is mounted on the front end of the motor and a specific gearing delivers the overall speed and output torque. There are several different types of gear motors, but in this post, we will focus on spur gears and planetary gears.

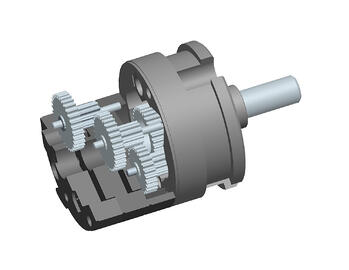

Spur gears

Spur gears are designed with one transmission point per stage and this technology has certain application advantages. One of the advantages of the spur gear is that it provides good performance – up to 90% – 95% per gear step – including ball bearing losses. In addition, the gearbox offers flexible diameters – it can be a long gearhead with a small diameter or a short gearhead with a larger diameter. You can also choose where to position the motor in relation to the output shaft, and the spur gear offers low noise compared to the planetary gear.

Planetary gear

Planetary gears, on the other hand, are based on 3 or 4 planet wheels per stage (however, more contact points or planets are possible as needed). The planetary gear also has many application benefits. Firstly, the gear unit offers high performance ranging from 85% to 90%. It also offers outstanding performance in a very compact gear design. You can expect fewer shocks in case of rapid change of motor rotation and a higher ratio per stage is possible, up to 7:1.

Conclusion

Start by finding the right gear motor that provides the maximum output torque for your application. It is common to see two torques – static and dynamic. Static torque refers to the maximum torque at zero speed, while dynamic torque refers to the torque at the given speed. It is typically a speed/torque curve showing the performance of the gear motor. Please contact usif you would like more information on the impact that higher speed will have on the overall lifetime of the gear motor.

Other important specifications to take note of are radial and axial load. This relates to the recommended specifications of the output shaft of the gear unit in the application.

Radial load refers to the force that can be applied to the shaft in the perpendicular direction and axial refers to the force that can be applied in the parallel direction.

The right gear motor that works best for your project or application, therefore, depends on several factors that should be known in order to get the best solution. We are at your disposal with our broad experience in electric motors, gears, and motor controls, and we are happy to help you find the ideal solution for your project.

Contact us on tel. +45 74 42 18 64 or by mail at info@gearcentralen.dk and have a non-binding talk with one of our skilled engineers – it’s completely free of charge.

Spur gear advantages

- Low friction per step, as a single gear is in contact with another

- Several steps can be configured to suit the purpose of the application

- Input and output shafts are not necessarily aligned

- Double output shafts are possible

- The direction of rotation can be reversed by using an odd number of reduction steps

Planetary gear benefits

- Higher reduction ratio per stage is possible compared to the composition of the spur gear

- It can deliver higher torque

- Input and output of a step have the same direction of rotation

- More rigid and compact construction